Quiet Luxury in Wood: Bespoke Millwork and Built-Ins

Materials That Whisper, Not Shout

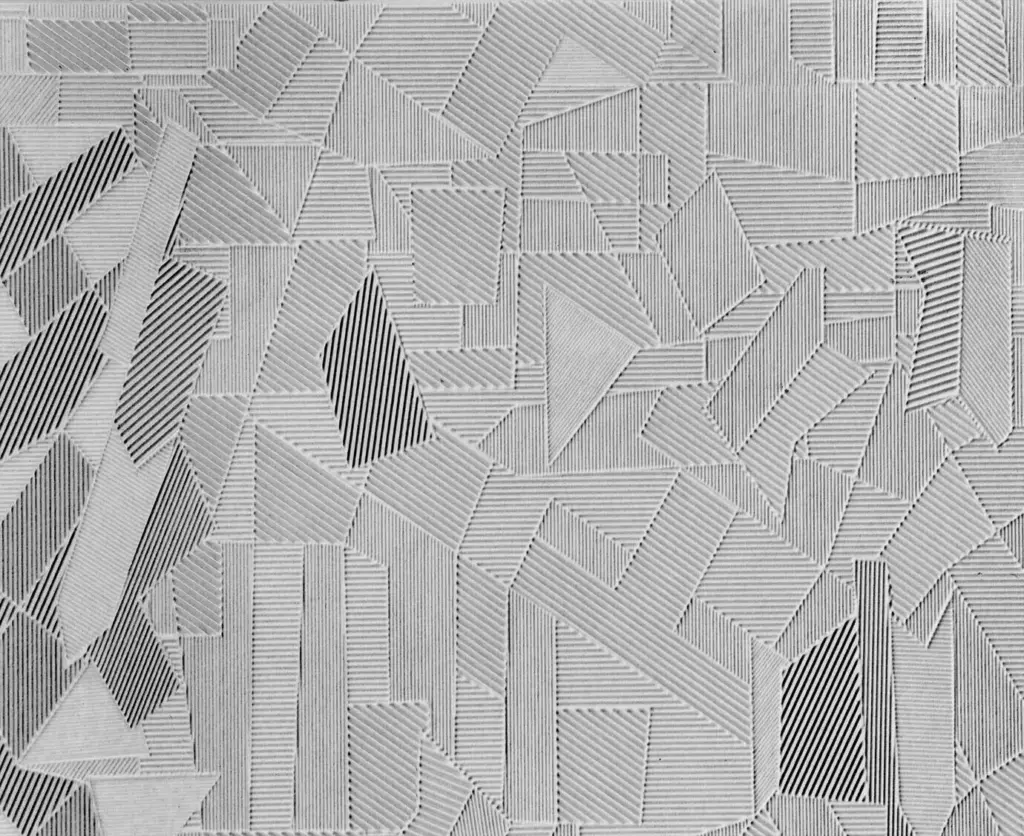

Shadow Lines and Proportions

A 3–5 mm shadow gap can visually separate cabinetry from walls, preventing bulky junctions and allowing walls to breathe. Aligning stiles with window mullions and electrical plates builds harmony across the room. Use the golden ratio sparingly as a sense-check, not a rule. Keep door modules consistent so the pattern repeats softly. Aim for edge thicknesses that feel intentional under the hand—neither chunky nor fragile. These fractional decisions shape calm more than ornament ever could.

Concealed Hardware and Touch-Open Magic

Push-to-open latches, integrated finger pulls, and recessed edge profiles keep faces unbroken while remaining practical for daily use. Employ soft-close hinges and under-mount slides rated for real weight, not theoretical loads. Test with full pantry contents, not empty drawers. Magnetic catches should feel gentle, never sticky. Where privacy matters, use pocketing doors to reveal work zones only when needed. The experience should be choreographed: approach, touch, open, stow, close—quietly satisfying every single time.

Flush Integration with Architecture

Set built-ins flush within plaster niches or align them with casings to convert furniture into architecture. Scribe to baseboards and ceiling irregularities so gaps vanish, then use minimal reveals to acknowledge movement and access. Coordinate with electricians early to conceal outlets inside drawers or in back panels. When cabinetry aligns with wall rhythms and sill heights, rooms feel resolved, as if designed together from day one, rather than layered from separate decisions made years apart.

Miters, Splines, and Invisible Strength

Sharp miters look effortless yet demand reinforcement. Hidden splines or dominoes add long-grain strength where fibers meet at forty-five degrees. Glue choices matter; polyurethane may creep, while PVA with proper clamp time holds predictably. Good shops pre-mill, rest, and finish-mill to relieve stresses. The payoff appears months later when seams remain tight. Ask to see a test corner cut open—evidence of reinforcement beats any promise. Quiet strength is the most reassuring luxury of all.

Handwork Where It Matters

CNC precision shines on repeatable parts, but hand planes, card scrapers, and block sanding still decide final feel at edges and reveals. Craftspeople tune door clearances by fractions till the close sounds right—more hush than click. They feather proud edges so fingers glide. They read grain to avoid tear-out on visible corners. This choreography of touch is rarely noticed, except when absent. The result: pieces that welcome contact rather than beg to be protected.

Stability Through Seasons

Wood moves. Responsible builders design for it. Back panels float, shelves breathe, and expansion is directed where eyes will not notice. Balancing veneer on both sides of a panel reduces cupping. Shops acclimate materials to site conditions before install. Homeowners can help too: maintain relative humidity around forty to fifty-five percent. When movement is anticipated instead of resisted, joints stay clean, doors stay true, and the calm appearance survives every season without drama.

Light, Texture, and the Art of Restraint

Function First: Built-Ins That Serve Quietly

Media Walls Without the Clutter

Kitchens That Breathe and Hide

Bedrooms and Wardrobes with Daily Ease

Process, Collaboration, and Long-Term Care

01

From Brief to Shop Drawings

Start with a narrative: how you cook, read, entertain, and charge devices. Translate that into adjacency diagrams, then elevations. Shop drawings pin down reveals, hinge swing, and outlet placement. Review full-size samples to confirm edge feel and sheen. Site surveys capture real-world wonkiness before cutting. Align trades early so mechanicals do not collide with cabinetry. Clarity here prevents change orders later and safeguards the delicate balance between minimal surfaces and everyday, hardworking function.

02

Installation Without Drama

The cleanest installs begin with protection: wrapped floors, padded routes, and labeled crates. Crews level and plumb first, then scribe carefully to walls that are never as straight as drawings suggest. Hardware is adjusted in small increments, then rechecked after a day. Electricians and millworkers coordinate final connections so lighting and doors do not compete for space. A quiet room emerges piece by piece, ending with a meticulous wipe-down and walkthrough that confirms every motion feels right.

03

Care Routines for Decades of Calm

Gentle cleaners, soft cloths, and a light touch preserve matte finishes. Avoid silicone polishes that build film. Refresh oil-wax systems when the surface looks thirsty; the process is simple and deeply satisfying. Keep humidity stable to minimize movement. Use coasters and trivets, yet welcome patina as a story, not a flaw. Photograph minor chips before service so repairs target exactly what changed. Share your experience in the comments, and subscribe for seasonal reminders and product updates.

All Rights Reserved.